Real-time dust monitoring in the cement production: reduced emissions and maintenance costs

CSN Group is a major integrated industrial group in Brazil, operating in cement, steel, mining, logistics and energy. It is present in 17 Brazilian states and abroad in Germany and Portugal.

In what context did you get in contact with ENVEA?

The furnace’s bag filters found at CSN cement plant in Paraiba, Brazil, includes 3200 bags elements. The site was equipped with a dust monitor in the stack. However, it couldn’t provide any accurate information in terms of filter failure. Therefore, the maintenance team had to conduct a comprehensive inspection of all 10 compartments and of the top of the bag house in order to detect dust accumulations. That resulted in high operating and maintenance costs due to excessive time spent by technicians and unnecessary bag replacements. We also experienced loss of “good” bags, low lifespan of the filtering elements, low reliability in the furnace’s filtering process and constant high-emission events.

What ENVEA solution was installed?

ENVEA offered a comprehensive solution featuring a dependable stack dust monitor (STACK 990),

10 sensors (LEAK LOCATE 320) to be installed within the bag filter and a data handling platform (Dust Tools). It allows to accurately alert and identify in real-time the source of problems, such as a broken bag, failure in a cleaning pulse valve, etc.

As a result, we are able to operate preventive maintenance that is cost-effective and guarantees low and controlled stack emissions.

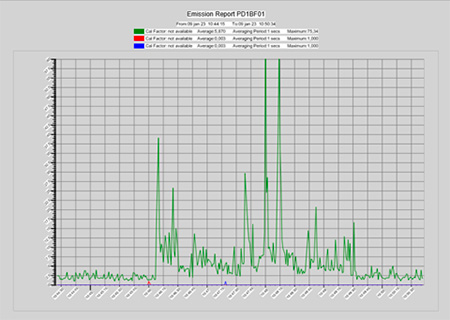

Thanks to the use of the Dust Tools platform, the process of checking the 3200 bags was reduced to only 20 bags. This also reduced the operating and maintenance costs, as well as eliminated unnecessary bag replacements and lost bags due to handling. Overall, we have experienced improved reliability in the entire process.

10 sensors (LEAK LOCATE 320) to be installed within the bag filter and a data handling platform (Dust Tools). It allows to accurately alert and identify in real-time the source of problems, such as a broken bag, failure in a cleaning pulse valve, etc.

As a result, we are able to operate preventive maintenance that is cost-effective and guarantees low and controlled stack emissions.

Thanks to the use of the Dust Tools platform, the process of checking the 3200 bags was reduced to only 20 bags. This also reduced the operating and maintenance costs, as well as eliminated unnecessary bag replacements and lost bags due to handling. Overall, we have experienced improved reliability in the entire process.

Why did you choose ENVEA?

CSN Group is an organization with multiple facilities in diverse regions both nationally and internationally. One of our core values and goals is to search for innovative and comprehensive solutions that can positively impact our resource management.

ENVEA team in Brazil demonstrated its expertise and provided us with excellent support, as well as direct technical assistance. Their complete solution is exactly what we had been searching for in recent years.

ENVEA team in Brazil demonstrated its expertise and provided us with excellent support, as well as direct technical assistance. Their complete solution is exactly what we had been searching for in recent years.

Emission Report from STACK 990 after the change of all 3200 bags.

Broken bag found after Leak Locate and Dust Tools report showed which row the issue was coming from

Verwandte Inhalte

Informationsanfrage