Monitoring material flow

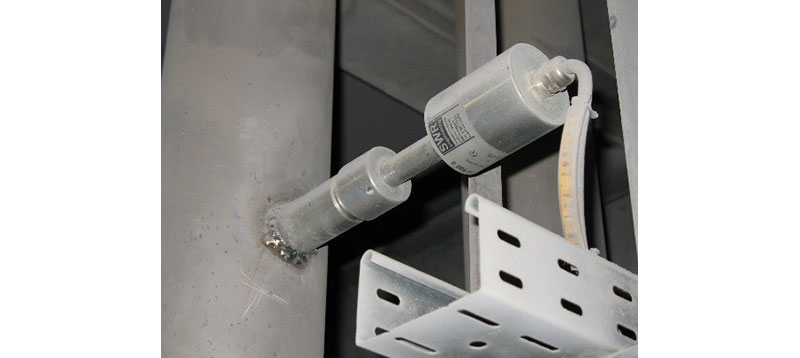

The FlowJam Plus offers the rapid detection of material movement (Flow/No Flow), as well as the additional function “Detection of blockage” or “Material flow interruption”. In the case of a material flow interruption it is now possible to quickly detect whether there is a problem, because the lower screw no longer removes any material or the feed screw no longer supplies material.

All members of the FlowJam family can be equipped with the optionally available process adapter, which allows operation at temperatures of up to 200°C and pressures up to 20 bar. At the same time, the process adapter makes operations with FlowJam S in Ex-Zone 20/22 possible. With ceramic mounting parts, a decoupling from very hot areas, such as cyclones, is possible.

The decisive advantage of the FlowJam over other methods of material flow monitoring, is its absolute lack of sensitivity regarding any soiling. The FlowJam can effortlessly detect through caked material, which always occurs in bulk material processes.

The monitoring of material flow through non-metallic materials, such as glass, PVC, ceramics and similar materials, expands the range of possibilities.

Fill level in raw process ?

Especially in raw process areas such as fluff dosages, stone-crushers or waste chutes, the advantages of the ProGap system compared to other technologies are clear. Damages through the material are excluded, since the installation takes place flush to the wall. The installation of the two parts that are identical in construction, transmitter and receiver, is generally carried out using a 1½“ threaded connector. But it is also possible to perform the installation with any other type of fitting that ensures that both the transmitter and receiver are correctly aligned with one another other.

Just as with material flow monitoring using FlowJam, the ProGap can also be equipped with the process adapter for temperatures up to 200 °C, pressures up to 20 bar and Ex-zone separation 20/22, as well as with the flange mounting for high-temperature areas. The ProGap can detect through all non-metallic materials (e.g. PVC, quartz glass, Plexiglas, and fireclay). Monitoring processes can thus be completely decoupled from the container interior.

Online recording of bulk material volumes

In combination with a patented measurement signal analysis, the SolidFlow 2.0 microwave sensor from envea™-SWR, for instance, supplies a direct measure for a mass flow of up to approx. 20 t/h. With this system, all powders, dusts and granulated material, up to the previously indicated volume, can be measured in freefall and in pneumatic lines. In the cement industry, the SolidFlow 2.0 has proven itself with the collection of aggregates, such as iron (II) sulfate and other additives, as well as in the measurement of carbon dust to the oven.

Today, the dosage of solid materials is often carried out volumetrically. The only indication for the setting of a desired volume is the rotational speed of mechanical delivery elements, usually rotary feeders or screw conveyors. However, since the material compressibility and fill level of the conveyor are demonstrably not always constant, there are often strong deviations between the target and actual discharge volumes. This results in quality fluctuations and unnecessary material waste, and thus increased costs.

Using radar technology, dosage controlled by rotary speed can be upgraded to regulated dosage, and without integrating a weighing installation that requires more effort and expense.

The SolidFlow 2.0 has an active roping compensation. Based on latest microprocessor-technology, the measuring signal is being dismantled in its frequency spectrum, which enables the sensor to compensate influences of roping.

Raw mix, cement, plaster, salt, gravel … – it does not matter which material needs to be measured in great mass flows (>20t/h). Mechanical procedures and the creation of more expensive installation heights can be avoided with the MaxxFlow HTC.

The MaxxFlow HTC is used in areas where large volumes of bulk material have to be measured after mechanical conveyor organs, such as spiral conveyors, pneumatic conveyor systems, rotary conveyors or similar mechanical discharge elements. The fact that here, too, no fittings of any kind have to be installed in the path of the delivery flow, the advantages of this technology are clearly recognizable. An upper limit for the throughput does not exist; any material volume can be measured – regardless of the hourly performance (50, 180, 290 t/h or more); the installation height of the sensor element amounts to 300 mm, which is why retrofitting in existing systems is easy. This is also due to the fact that the installation position is completely arbitrary. MaxxFlow HTC has an extremely abrasion-resistant, ceramic interior; the system can be used up to a material temperature of 120 °C. If used in new systems, its small dimensions can often result in a reduction in installation height, which previously had to be planned for mechanical measuring devices. In case of continuous extraction, the transmitter can be installed immediately after the discharge of the conveyor organ, even though discharge sections are generally not required. The measurement is equally independent of the flow rate as it is of the flow pattern of the conveyed material in the line.

Among other places, the MaxxFlow HTC is used in several cement plants in which the measurement of cement volume is used as a reference input variable for the iron (II) sulfate addition. In additional applications, also in the cement area, the raw mix volume is recorded. This makes it possible to ensure the required mix ratios are respected and thus providing an output of constant quality.

Determination of material moisture

The most important prerequisite for a correct measurement of the residual moisture in bulk material is the correct selection of the installation location for the sensor. For bulk material slides or conveyor belts, care must be taken that the material is guided above the probe at a layer thickness that is as even as possible. The installation of the M-Sens 2 in spiral conveyors has proven to be especially advantageous. As output, the user receives a 4 – 20 mA signal, as well as 2 alarm contacts. The sensor may be installed in all Ex-zones (gas & dust) and up to a temperature of 120 °C.

Dust monitoring

The Dusty is a filter monitor that works on a triboelectric basis. This means that as soon as there is movement, electrically charged dust particles impact the sensor or fly past it, then an electric charge of the particles is transferred to the sensor rod. These very small signals are reinforced with the electronics and thus made visible. The Dusty can be used in metal channels in which dust particles are to be detected in flowing gas. Its operational range starts at dust volumes of 0.1 mg/m3. In systems with explosion hazard area zone 22, the “Dusty DustEx 22” type can be applied. Due to its speed and reliability, the Dusty can also be used optimally as an alternative and/or expansion to the “police filter” as well as an alternative to the differential pressure measurement.

enveaTM – SWR engineering Messtechnik GmbH · www.swr-engineering.com · a.schmedt@swr-engineering.com

Gutedelstr. 31 · 79418 Schliengen (Germany) · Tel. +49(0)7635-8272-49 · Fax +49(0)7635-8272-48-48