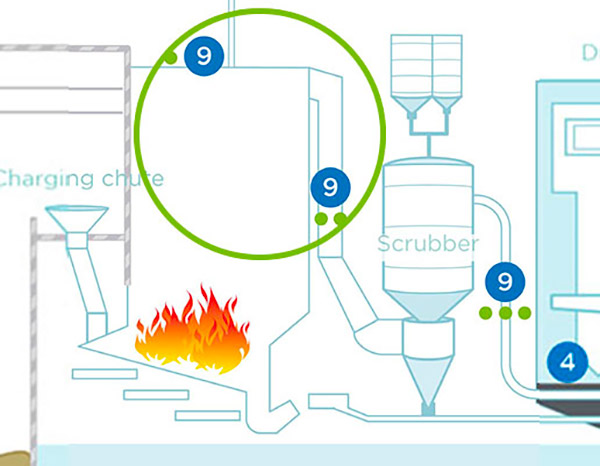

APPLICATION

Gas monitoring at the boiler outlet

Combustion optimization is not only a question of power. Monitoring the flue gases on a boiler or burner, makes sense ecologically as well as economically. Poor combustion can produce corrosive compounds and ash deposits in the boiler itself. To avoid damage due to these by-products, combustion must be accurately evaluated by monitoring mainly the O2 and the CO.

SOLUTION

The MIR 9000e can measure simultaneously and continuously up to 8 parameters, depending on your selection: NO, SO2, CO, CO2, CH4, N2O, O2 and residual H2O) including greenhouse gases.

The gas monitor utilizes the most recent optical and electronic technologies offering increased precision and robustness, while requiring only limited maintenance and ultra low power consumption. Thanks to its breakthrough mechanical design for weight and power saving as well as its exclusive “inside the box” modular concept, the monitor is insensitive to T° variations in the range +5° to +40°C (no air conditioning required).

Smart and connected, with one click access to key functions via touchscreen or via full remote access to full operation from computer through TCP/IP connexion or on smartphone, through ENVEA Connect™ App (free download) and proprietary WiFi. Smartphone alerts and notifications, software updates, direct access to real-time and stored data with time frame selection to generate graphs, embedded Communication Protocol for DAHS software (WEX®) with automatic recognition and configuration, IoT services, etc. are just some of the ultra-innovative features that have been implemented in this highly innovative system.

Other compatible solutions from ENVEA are the MIR 9000H, the MIR IS or the in-situ monitor LAS 5000XD based on the TDL technology are used for online monitoring of gas parameters and able to measure in real time and simultaneously these 2 species and more, such as HCl, NH3 etc. if they are required by the process.

CUSTOMER BENEFITS

- The MIR 9000e includes smart operations and AMS control functionalities: integrated sampling control, automatic zero and span gas injection, external pump control, system alarms display, etc.

- The analyzer is compatible with any type of drying technology (gas cooler, permeation, dilution…).

- Measuring continuously the O2 and CO allow for immediate adjustment of the air injection and better control of feeders, and so to optimize the efficiency of the combustion process.

- Reduces the long-term impact of the CO corrosion load to the boiler wall

- Extremely compact analyzer (19’’- 3U & only 33cm/13” depth), it guarantees easy turnkey integration and seamless retrofit of existing gas cabinets of nearly all manufacturers on the market.

Verwandte Inhalte

Informationsanfrage